Day 4 - Section 1 - Introduction to 3D printing

| Site: | ΕΛ/ΛΑΚ Moodle |

| Course: | Robotics - 3D Printing - Internet of Things |

| Book: | Day 4 - Section 1 - Introduction to 3D printing |

| Printed by: | Guest user |

| Date: | Friday, 2 January 2026, 1:52 AM |

Description

- describe what is 3D printing

- state the stages of 3D Printing

- describe the Modelling stage

- describe the Printing stage

- describe the Finishing stage

Chapter 4.1 - Let's print anything!

3D printing, also known as additive manufacturing (AM), refers to processes used to create a three-dimensional object in which layers of material are formed under computer control to create an object. Objects can be of almost any shape or geometry and typically are produced using digital model data from a 3D model or another electronic data source such as an Additive Manufacturing File (AMF) file. Stereolithography (STL) is one of the most common file types that is used for 3D Printing. Thus, unlike material removed from a stock in the conventional machining process, 3D printing or AM builds a three-dimensional object from computer-aided design (CAD) model or AMF file by successively adding material layer by layer.

The term "3D printing" originally referred to a process that deposits a binder material onto a powder bed with printer heads layer by layer. More recently, the term is being used in popular vernacular to encompass a wider variety of additive manufacturing techniques. United States and global technical standards use the official term additive manufacturing for this broader sense.

Chapter 4.2 - Modeling, Printing, Finishing...

Modelling

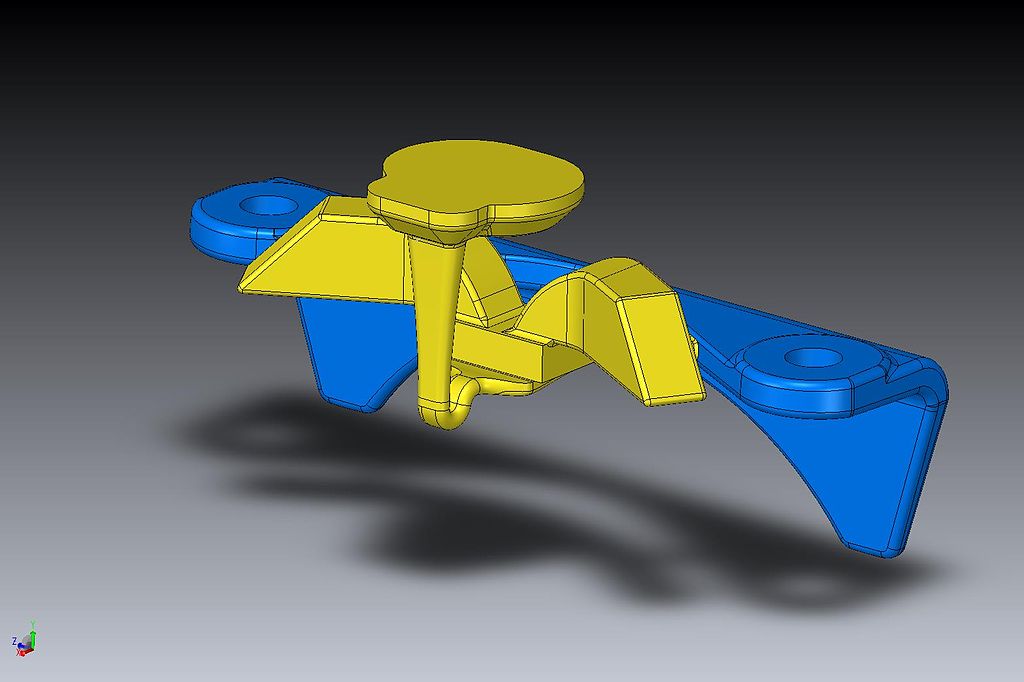

3D printable models may be created with a computer-aided design (CAD) package, via a 3D scanner, or by a plain digital camera and photogrammetry software. 3D printed models created with CAD result in reduced errors and can be corrected before printing, allowing verification in the design of the object before it is printed.

Printing

Construction of a model with contemporary methods can take anywhere from several hours to several days, depending on the method used and the size and complexity of the model. Additive systems can typically reduce this time to a few hours, although it varies widely depending on the type of machine used and the size and number of models being produced simultaneously.

Traditional techniques like injection moulding can be less expensive for manufacturing polymer products in high quantities, but additive manufacturing can be faster, more flexible and less expensive when producing relatively small quantities of parts. 3D printers give designers and concept development teams the ability to produce parts and concept models using a desktop size printer.

Finishing

Though the printer-produced resolution is sufficient for many applications, printing a slightly oversized version of the desired object in standard resolution and then removing material with a higher-resolution subtractive process can achieve greater precision.

Some printable polymers such as ABS, allow the surface finish to be smoothed and improved using chemical vapor processes based on acetone or similar solvents.

Some additive manufacturing techniques are capable of using multiple materials in the course of constructing parts. These techniques are able to print in multiple colors and color combinations simultaneously, and would not necessarily require painting.

Some printing techniques require internal supports to be built for overhanging features during construction. These supports must be mechanically removed or dissolved upon completion of the print.

All of the commercialized metal 3D printers involve cutting the metal component off the metal substrate after deposition. A new process for the GMAW 3D printing allows for substrate surface modifications to remove aluminum or steel.